It is essential to have a tool that can reduce the uncertainties associated with manufacturing complex parts and intricate designs!!

SOFTWARE OVERVIEW

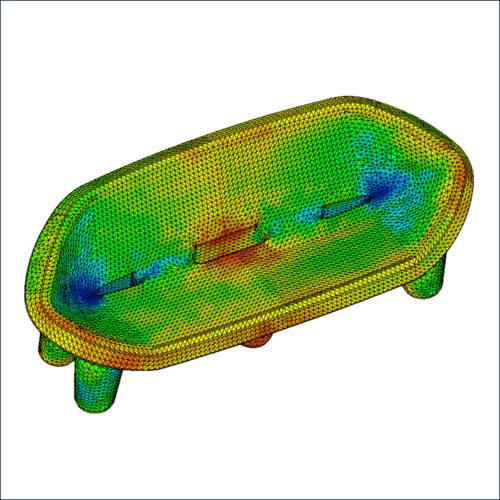

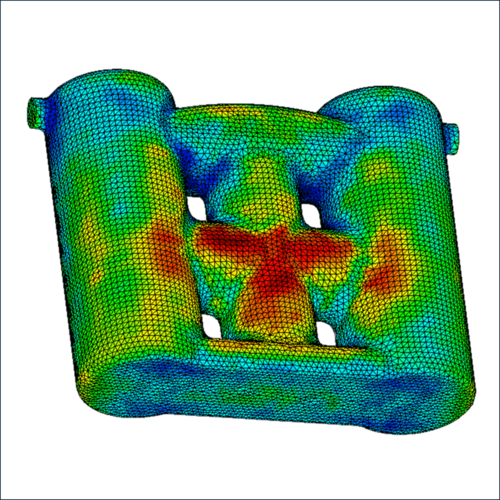

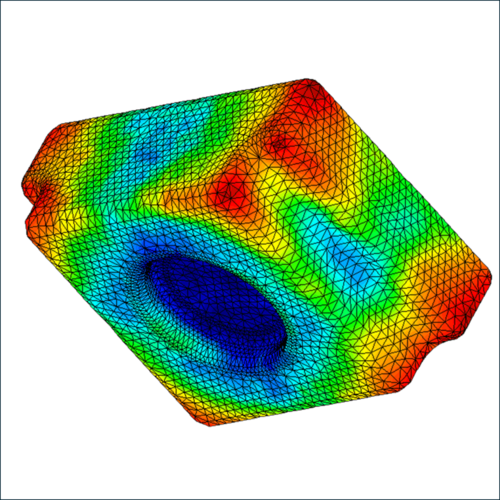

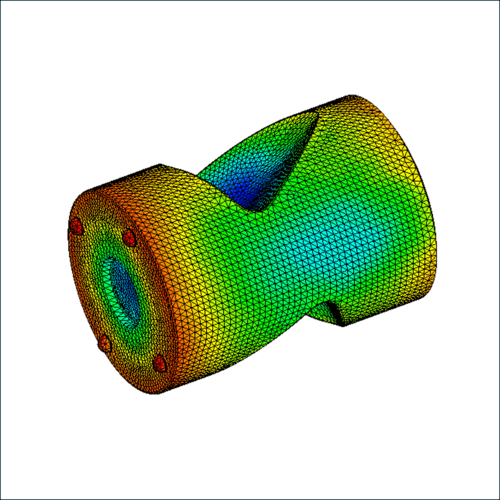

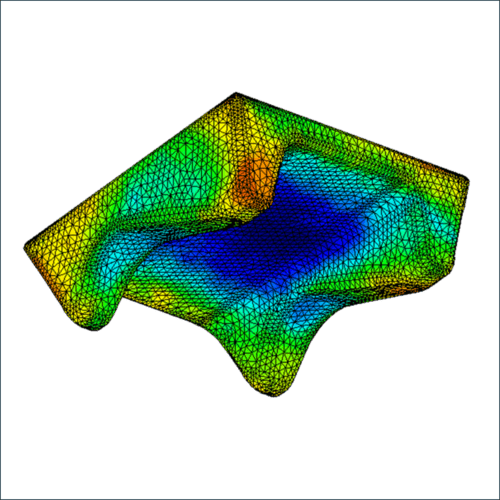

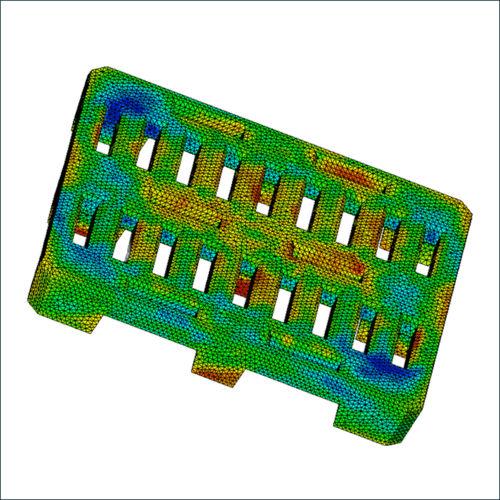

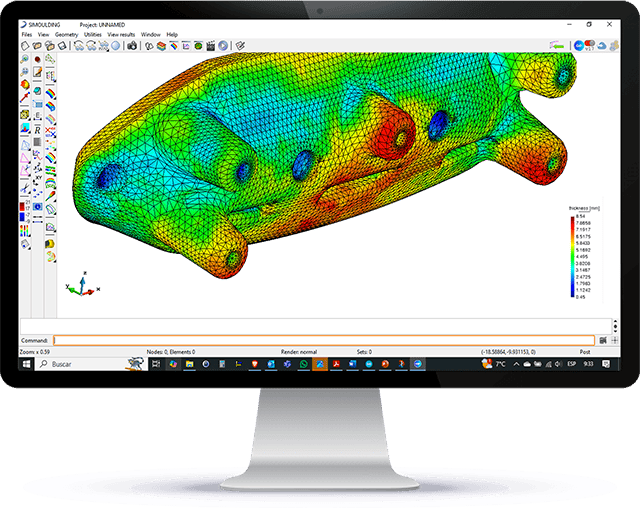

SIMOULDING is a simulation software that allows you to load a part's geometry into the program and predict the wall thickness distribution of the rotationally molded part, among other characteristics. The system is configured similarly to a rotational molding machine, entering the type of rotation (e.g., biaxial or Rock & Roll), the mould position on the machine plates, rotation speeds, oven temperature, heating time, cooling type, etc. If some areas of the mould are protected or receive additional heat, this information can also be entered.

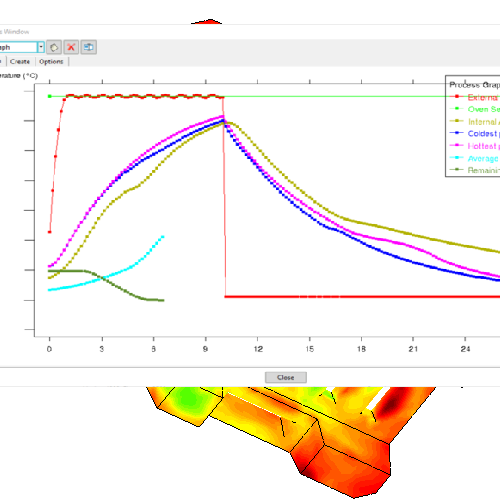

The program will then predict the temperature profiles of the mould and the internal air, calculate the movement of the material within the mould, and calculate all the physical variables to perform the simulation.

In addition to the thickness of the part at each point on its surface, a number of very useful results and data can be obtained that will help understand and improve both the design process and the processing parameters.

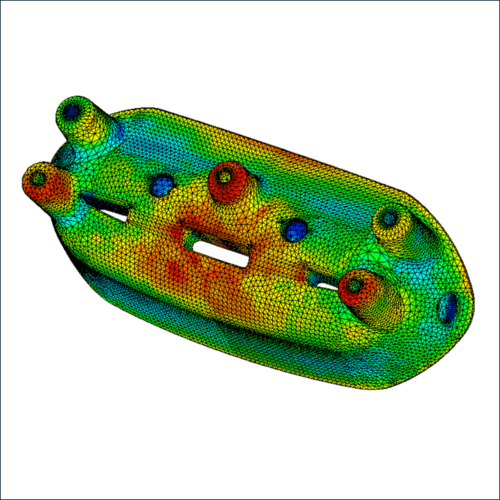

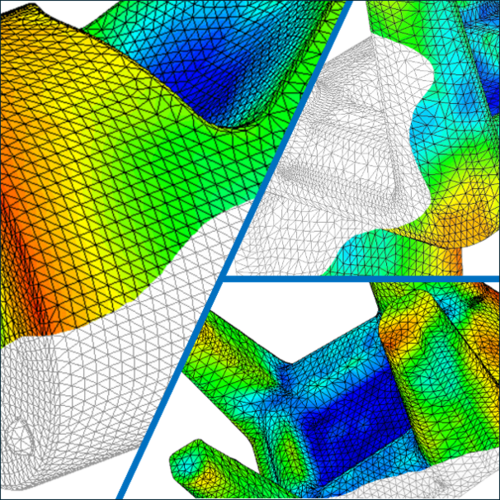

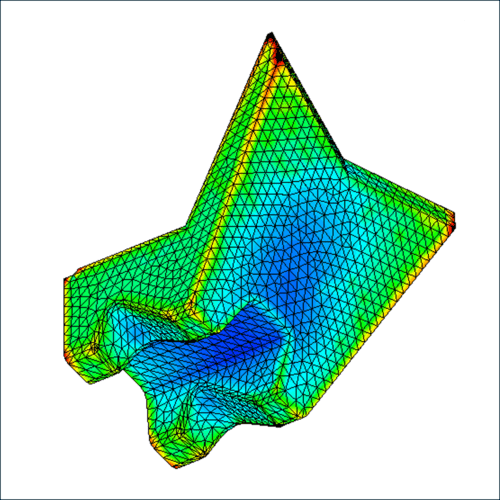

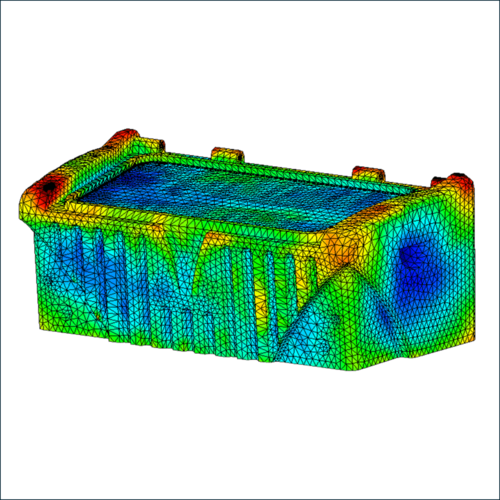

All results can be visualized on the surface of the part using distribution mapping.

The available results are as follows:

BENEFITS

This simulation package offers numerous advantages to designers, engineers and rotational molders. Not only is it useful as a training package for exploring all kinds of what-if scenarios, but it also provides practical insights into part design and optimal machine setup.

Before mould manufacturing, it is possible to take the CAD geometry of the part and use simulation to anticipate future problems by minimizing the uncertainties associated with moulding.

Minimize process uncertainties

Minimize process uncertainties

Address proper thickness distribution

Address proper thickness distribution

Optimize the amount of material used

Optimize the amount of material used

Avoid products that do not meet

requirements

Avoid products that do not meet

requirements

Avoid corrections and modifications to

moulds

Avoid corrections and modifications to

moulds

Avoid delays in launching the product to

market

Avoid delays in launching the product to

market

GET MORE COMPETITIVE PRODUCTS!!

TRY A DEMO

The software runs on a PC, compatible with Windows 10 or newer

V_1.2

SUPPORT

For personalized help, please contact the email address found in the Help menu of the software

REQUEST INFORMATION

Contact us today to learn how SIMOULDING can help you minimize uncertainties, avoid costly mould corrections, and launch competitive products faster.

Please complete the form below and we will contact you shortly.

REQUEST INFORMATION